3x12 Wood Beam Span Calculator - Deflection and Load Analysis

3x12 Wood Beam Overview

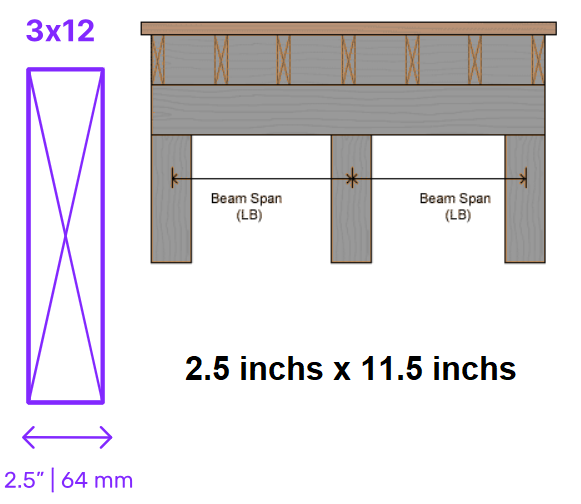

3x12 Wood Beam is a large-sized lumber used for heavy-duty construction projects that require significant load-bearing capacity. Below are its key details:

- Nominal Size: 3 inches × 12 inches

- Actual Size: Typically 2.5 inches × 11.25 inches (64mm × 286mm)

- Materials: Made from softwood (e.g., Douglas fir, pine) or hardwood (e.g., oak, maple).

- Applications:

- Load-bearing beams for floors, roofs, and bridges

- Heavy-duty framing in large construction projects

- Support for large, expansive structures

- Commercial and industrial buildings

- Advantages: Strong and durable, ideal for large construction projects requiring high load-bearing capacity.

- Limitations: Heavyweight, requiring specialized equipment and labor for handling and installation.

3x12 wood beams are well-suited for large-scale construction projects that demand superior strength and stability, offering reliable support in commercial, industrial, and heavy-duty applications.

Deflection of a Wood Beam Formula

To calculate the deflection of a wood beam with a rectangular cross-section, use the following formula:

\[ \delta = \frac{5 \cdot w \cdot L^4}{384 \cdot E \cdot I} \]

Where:

- \(\delta\) (Deflection):

- The deflection at the midspan of the wood beam in inches.

- \(w\) (Uniform Load):

- The uniformly distributed linear load applied to the beam, in pound-force per inch (lbf/in).

- \(L\) (Beam Span):

- The span or unbraced length of the beam in inches.

- \(E\) (Modulus of Elasticity):

- The modulus of elasticity of the wood species used, in pounds per square inch (psi).

- \(I\) (Moment of Inertia):

- The area moment of inertia of the beam's cross-section, in inches to the fourth power (in\(^4\)).

We calculate the area moment of inertia (\(I\)) of the beam's cross-section using this formula:

\[ I = \frac{b \cdot d^3}{12} \]

Where:

- \(I\):Area moment of inertia in inches to the fourth power (in\(^4\)).

- \(b\):Actual base width or thickness of the lumber in inches.

- \(d\):Actual height of the lumber in inches.

To calculate the actual bending stress, we use this formula:

\[ f_b = \frac{M}{S} \]

Where:

- \(f_b\):Bending stress in pounds per square inch (psi).

- \(M\):Bending moment in pound-force inches (lbf·in).

- \(S\):Section modulus in cubic inches (in\(^3\)).

The bending moment \(M\) is calculated as:

\[ M = 1/8 (\cdot w \cdot L^2) \]

Where:

- \(w\):Uniformly distributed load in pound-force per inch (lbf/in).

- \(L\):Beam span or unbraced length in inches.

The shear force \(V\) is calculated as:

\[ V = \cdot w \cdot L / 2 \]

We calculate the actual shear stress (\(f_v\)) by dividing the shear force by the cross-sectional area of the beam:

\[ f_v = \frac{V}{A} \]

Where:

- \(f_v\):Shear stress in pounds per square inch (psi).

- \(V\):Shear force in pound-force (lbf).

- \(A\):Cross-sectional area of the beam in square inches (in\(^2\)).

Wood Species - Modulus of Elasticity (E ×106 psi)

| Species | No. 1 | No. 2 | No. 3 | Stud | Const. | Standard | Utility |

|---|---|---|---|---|---|---|---|

| Alaska Cedar | 1.3 | 1.2 | 1.1 | 1.1 | 1.2 | 1.1 | 1.0 |

| Alaska Spruce | 1.5 | 1.4 | 1.3 | 1.3 | 1.3 | 1.2 | 1.1 |

| Alaska Yellow Cedar | 1.4 | 1.3 | 1.2 | 1.2 | 1.3 | 1.1 | 1.1 |

| Beech-Birch-Hickory | 1.6 | 1.5 | 1.3 | 1.3 | 1.4 | 1.3 | 1.2 |

| Coast Sitka Spruce | 1.5 | 1.5 | 1.4 | 1.4 | 1.4 | 1.3 | 1.2 |

| Douglas Fir-Larch | 1.7 | 1.6 | 1.4 | 1.4 | 1.5 | 1.4 | 1.3 |

| Douglas Fir-Larch (North) | 1.8 | 1.6 | 1.4 | 1.4 | 1.5 | 1.4 | 1.3 |

| Douglas Fir-South | 1.3 | 1.2 | 1.1 | 1.1 | 1.2 | 1.1 | 1.0 |

| Eastern Hemlock-Balsam Fir | 1.1 | 1.1 | 0.9 | 0.9 | 1.0 | 0.9 | 0.8 |

| Eastern White Pine | 1.1 | 1.1 | 0.9 | 0.9 | 1.0 | 0.9 | 0.8 |

| Hem-Fir | 1.5 | 1.5 | 1.3 | 1.2 | 1.3 | 1.2 | 1.1 |

| Hem-Fir (North) | 1.7 | 1.6 | 1.4 | 1.4 | 1.5 | 1.4 | 1.3 |

| Mixed Maple | 1.2 | 1.1 | 1.0 | 1.0 | 1.1 | 1.0 | 0.9 |

| Mixed Oak | 1.0 | 0.9 | 0.8 | 0.8 | 0.9 | 0.8 | 0.8 |

| Mixed Southern Pine | 1.5 | 1.4 | 1.2 | 1.2 | 1.3 | 1.2 | 1.1 |

| Northern Red Oak | 1.4 | 1.3 | 1.2 | 1.2 | 1.2 | 1.1 | 1.0 |

| Northern White Cedar | 0.7 | 0.7 | 0.6 | 0.6 | 0.7 | 0.6 | 0.6 |

| Norway Spruce (North) | 1.3 | 1.3 | 1.2 | 1.2 | 1.2 | 1.1 | 1.1 |

| Red Maple | 1.6 | 1.5 | 1.3 | 1.3 | 1.4 | 1.3 | 1.2 |

| Red Oak | 1.3 | 1.2 | 1.1 | 1.1 | 1.2 | 1.1 | 1.0 |

| Redwood | 1.3 | 1.2 | 1.1 | 0.9 | 0.9 | 0.9 | 0.8 |

| Southern Pine | 1.6 | 1.4 | 1.3 | 1.3 | 1.4 | 1.2 | 1.2 |

| Spruce-Pine-Fir | 1.4 | 1.4 | 1.2 | 1.2 | 1.3 | 1.2 | 1.1 |

| Spruce-Pine-Fir (South) | 1.2 | 1.1 | 1.0 | 1.0 | 1.0 | 0.9 | 0.9 |

| Western Cedars | 1.0 | 1.0 | 0.9 | 0.9 | 0.9 | 0.8 | 0.8 |

| White Oak | 1.0 | 0.9 | 0.8 | 0.8 | 0.9 | 0.8 | 0.8 |

| Yellow Cedar | 1.4 | 1.4 | 1.2 | 1.2 | 1.3 | 1.2 | 1.1 |

Home

Home Back

Back